Kaya

18-8 / A2 bakin karfe hex kwayoyi

muhawara

| Sunan Samfuta | Bakin karfe hex kwayoyi |

| Abu | An yi shi ne daga 18-8 Bakin Karfe, waɗannan kwayoyi suna da juriya na sinadarai kuma suna iya zama kamar saɓin magnetic. Su kuma ana kiranta da karfe na karfe. |

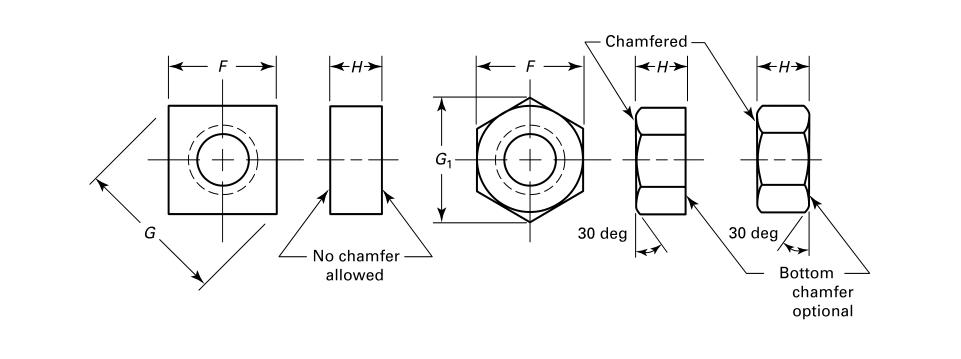

| Nau'in siffar | Hex kwaro. |

| Na misali | Kwayoyi waɗanda ke haɗuwa a Asme B18.2.2 ko Din miliyan 934 sun cika waɗannan ka'idodin girma. |

| Appliation | Wadannan kwayoyi sun dace da saurin kayan masarufi da kayan aiki. |

roƙo

Bakin karfe hex kwayoyi ne tare da sutturar da aka tsara, da aka tsara da za a yi amfani da su tare da ƙirar da sukurori don amintattun abubuwa biyu ko fiye. Wadannan kwayoyi an yi su ne daga bakin karfe, wanda ke ba da kyakkyawan lalata juriya, mai sanya su ya dace da wadatattun aikace-aikace, musamman a cikin yanayin danshi, sunadarai, ko abubuwan da basu dace ba. Ga wasu Aikace-aikace gama gari don ƙwaya na bakin karfe:

Masana'antar Gina:

Ana amfani da kwayoyi na hex don yin sauri, kamar katako, ginshiƙai, da kuma goyan baya, inda jingina yake da mahimmanci.

Automotive:

Amfani da masana'antar mota da kuma gyara don kiyaye abubuwa masu yawa, ciki har da sassan injin, tursasawa, da abubuwan shayes.

Kayan masana'antu da masana'antu na kayan aiki:

Amfani a cikin taron kayan masarufi da kayan aiki, samar da ingantaccen haɗi tsakanin sassa daban-daban.

Lantarki da lantarki:

Ana amfani da kwayoyi na hex a cikin taron pantels na lantarki, sarrafa katunan kayatarwa, da sauran kayan aikin lantarki.

Aikace-aikacen Marine:

Bakin karfe masu ƙarfe ne na bakin ciki sune masu tsayayya kuma suna neman amfani a cikin aikin jirgin ruwa da kuma gyara cikin yanayin ruwa.

Ayyukan makamashi mai sabuntawa:

An yi amfani da shi a cikin gina iska mai iska, tsarin aikin hasken rana, da sauran kayan aikin sabunta makamashi mai sabuntawa.

| Maras muhimmanci Gimra | Babban manyan diamita na zaren | Fadi da filaye, f | Nisa a duk fadin sasanninta | Kauri, h | Ɗauke da tsintsiya don Hread Ais, Fim | ||||||

| Square, g | Hex, g1 | ||||||||||

| Na asali | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | |||

| 0 | 0.060 | 5/32 | 0.150 | 0.156 | 0.2026 | 0.221 | 0.171 | 0.180 | 0.043 | 0.050 | 0.005 |

| 1 | 0.073 | 5/32 | 0.150 | 0.156 | 0.2026 | 0.221 | 0.171 | 0.180 | 0.043 | 0.050 | 0.005 |

| 2 | 0.086 | 3/16 | 0.180 | 0.188 | 0.247 | 0.265 | 0.205 | 0.217 | 0.057 | 0.066 | 0.006 |

| 3 | 0.099 | 3/16 | 0.180 | 0.188 | 0.247 | 0.265 | 0.205 | 0.217 | 0.057 | 0.066 | 0.006 |

| 4 | 0.112 | 1/4 | 0.241 | 0.250 | 0.331 | 0.354 | 0.275 | 0.289 | 0.087 | 0.098 | 0.009 |

| 5 | 0.125 | 5/16 | 0.302 | 0.312 | 0.415 | 0.442 | 0.344 | 0.361 | 0.102 | 0.114 | 0.011 |

| 6 | 0.138 | 5/16 | 0.302 | 0.312 | 0.415 | 0.442 | 0.344 | 0.361 | 0.102 | 0.114 | 0.011 |

| 8 | 0.164 | 11/32 | 0.332 | 0.344 | 0.456 | 0.486 | 0.378 | 0.397 | 0.117 | 0.130 | 0.012 |

| 10 | 0.190 | 3/8 | 0.362 | 0.375 | 0.497 | 0.530 | 0.413 | 0.433 | 0.117 | 0.130 | 0.013 |

| 12 | 0.216 | 7/16 | 0.423 | 0.438 | 0.581 | 0.691 | 0.482 | 0.505 | 0.148 | 0.161 | 0.015 |

| 1/4 | 0.250 | 7/16 | 0.423 | 0.438 | 0.581 | 0.691 | 0.482 | 0.505 | 0.178 | 0.193 | 0.015 |

| 5/16 | 0.312 | 9/16 | 0.545 | 0.562 | 0.748 | 0.795 | 0.621 | 0.650 | 0.208 | 0.225 | 0.020 |

| 3/8 | 0.375 | 5/8 | 0.607 | 0.625 | 0.833 | 0.884 | 0.692 | 0.722 | 0.239 | 0.257 | 0.021 |